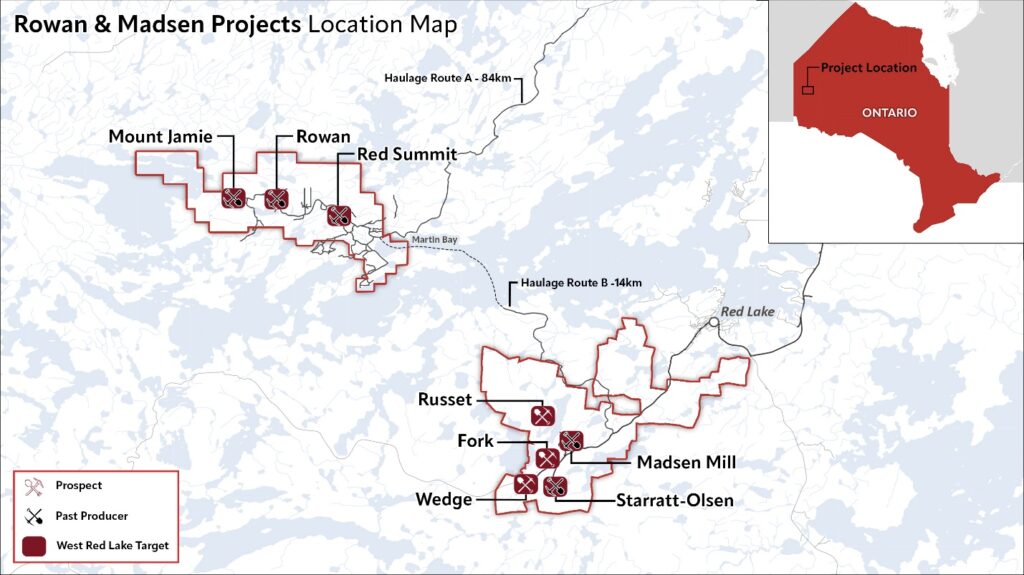

West Red Lake Gold Mines Ltd. (“West Red Lake Gold” or “WRLG” or the “Company”) (TSXV: WRLG) (OTCQB: WRLGF) is very pleased to announce positive metallurgical testresults from the Rowan Mine Deposit, which is part of the 100% owned Rowan Property located in the prolific Red Lake Gold District of Northwestern Ontario, Canada.

Highlights of Metallurgical Test Results

The Rowan Mine Deposit exhibits an excellent response using conventional metallurgical techniques with a very high percentage of Gravity Recoverable Gold (“GRG”). As expected, the GRG component occurs as coarse gold, which is also seen at Madsen and the satellite deposits Russet, Fork and Wedge (the “Satellites”). The metallurgical test work was completed using the Madsen Mill Flowsheet with the samespecifications and parameters currently in place at the Madsen Mill.

• Test work completed on the Rowan Master Composites (“MCs”) indicates that Rowan veinmaterial can be processed through the Madsen Mill with minor changes to the existing flowsheet.

• The results indicate the MCs tested produce very high gravity recovery with overall gold extraction above 98% after a 48-hour cyanide leach of the gravity tailings.

• Gravity Recoverable Gold (GRG) ranged from 75.8% to 94.9% and the gold was found to be coarse to very coarse.

• At a primary grind of 80% passing (P80) 75 microns, very low cyanide consumptions, below 0.23 kilogram per tonne (“kg/t”), were required to achieve gold extractionsabove 98%.

Shane Williams, President & CEO, stated, “The results of this first phase of metallurgical test work at Rowan have exceeded our expectations, and represent a significant step forward in de-risking this high-grade resource. It is very encouraging to see gold recoveries in the order of 98% using the same process flow sheet as the Madsen Mill. Furthermore, the high percentage of gold that is able to be extracted via gravity methods only further increases our confidence in the Rowan Deposit as a futuresource of high-grade, easily recoverable gold ounces that could potentially add a significant boost to the overall production profile at Madsen.”

Details of Metallurgical Program

The metallurgical test program (the “Program”) was completed by Base Metallurgical Laboratories (“BaseMet”), a leading metallurgical testing and consulting firm based in Kamloops, British Columbia. The test work was completed on four (4) MCsamples representative of Rowan vein zones 101, 102, 103 and 104 (“MC-101”, “MC-102”, “MC-103” and “MC-104”, respectively). The MC samples were created from contiguous intervals of material from 14 NQ-diameter diamond drill holes throughout the Rowan deposit. The metallurgical test program was designed and supervised by Kelly McLeod, P.Eng. (K-Met Consultants, Inc.).

TABLE 1 shows the head grades for the four MCs. Due to the nuggety nature of the gold in the material, MC head grades vary with each test charge – for example, a range of 4.6 to 15.3 g/t Au was measured during the leach tests.

| Products | Assays | |||||||

| Au (g/t) | Ag (g/t) | As (g/t) | Cu (%) | Fe (%) | S (%) | C (%) | ||

| MC 101 Hd 1 | 5.56 | 2.0 | 96 | 0.008 | 2.06 | 0.50 | 0.33 | |

| MC 101 Hd 2 | 6.32 | 1.3 | 104 | 0.008 | 2.08 | 0.52 | 0.34 | |

| Average | 5.94 | 1.7 | 100 | 0.008 | 2.07 | 0.51 | 0.34 | |

| MC 102 Hd 1 | 11.10 | 1.5 | 412 | 0.004 | 1.62 | 0.41 | 0.46 | |

| MC 102 Hd 2 | 8.01 | 2.6 | 324 | 0.004 | 1.58 | 0.47 | 0.46 | |

| Average | 9.56 | 2.1 | 368 | 0.004 | 1.60 | 0.44 | 0.46 | |

| MC 103 Hd 1 | 3.22 | 2.8 | 1754 | 0.018 | 5.44 | 1.95 | 0.61 | |

| MC 103 Hd 2 | 3.40 | 2.8 | 1470 | 0.017 | 5.64 | 1.88 | 0.64 | |

| Average | 3.31 | 2.8 | 1612 | 0.018 | 5.54 | 1.92 | 0.63 | |

| MC 104 Hd 1 | 3.67 | 1.6 | 12 | 0.013 | 14.2 | 0.89 | 0.55 | |

| MC 104 Hd 2 | 1.00 | 1.6 | 12 | 0.013 | 13.9 | 0.87 | 0.55 | |

| Average | 2.34 | 1.6 | 12 | 0.013 | 14.1 | 0.88 | 0.55 | |

Discussion of the Metallurgical Program Results

The preliminary test work completed on the Rowan MCsindicates the material can be processed through the Madsen Mill with minor changes to the existing flowsheet. The results indicate the MCs tested produced very high gravity recovery with overall gold extraction after a 48-hour cyanide leach of the gravity tailings above 98%. Like Madsen, the leach tests were completed at low cyanide consumptions and successfully achieved the target Cyanide Weak Acid Dissociable (“CNWAD“) in the final tailings of less than 1 ppm using the previously established Madsen conditions for cyanide destruction.

Mineralogy and Comminution

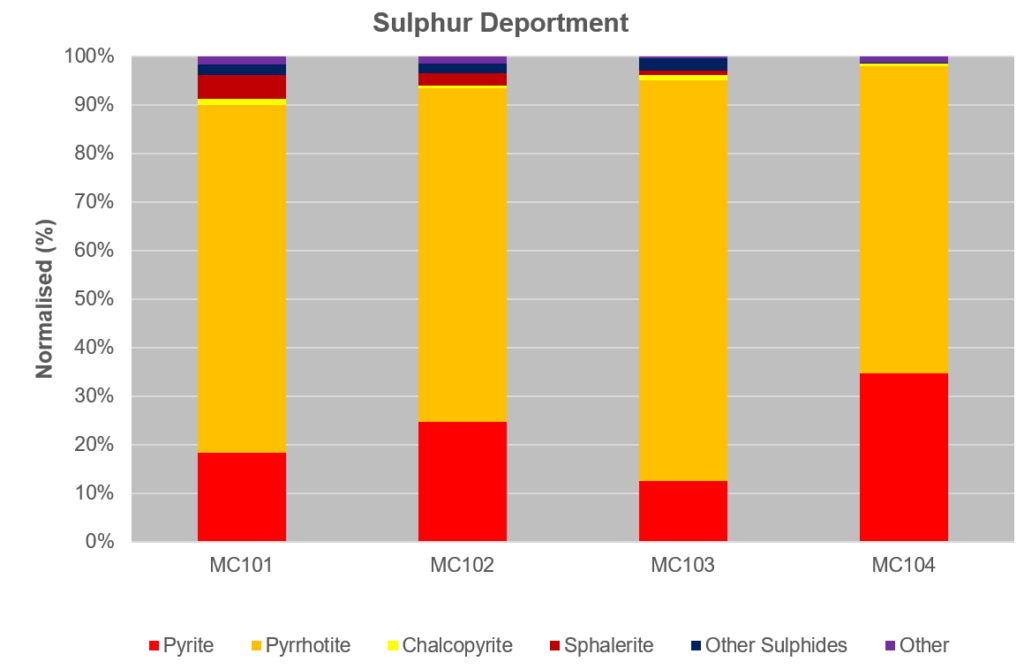

Bulk Mineralogy Analysis (“BMA”) was completed on all four MC samples. As observed at Madsen and the Satellite deposits, the main sulphides present are pyrrhotite followed by pyrite.Sphalerite is also present at Rowan and tends to often bespatially associated with visible gold.

Comminution test work conducted on the MCs yielded the following results:

• The Rowan samples tested were harder than the Madsen and Satellite deposits.

• The Bond Ball Work Index (“Bwi”) for the Rowan MCs ranges from 16.2 to 18.2 kilowatt-hour per tonne (“kWh/t”) – for comparison Madsen ranges from 9.7 to 17.1 kWh/t and averages 14.4 kWh/t.

• The SAG Mill Comminution (“SMC”) test results are outlined in TABLE 3 below.

| Sample ID | Bond BWI @ 106µm CSS | |||

| F80-μm | P80-μm | Gpr | kW-hr/t | |

| MC-101 | 2493 | 74 | 1.02 | 17.2 |

| MC-102 | 2537 | 75 | 1.1 | 16.2 |

| MC-103 | 2284 | 76 | 1.08 | 16.8 |

| MC-104 | 2625 | 74 | 0.94 | 18.2 |

| Sample ID | Size Fraction Tested (mm) | DWi | DWi | Mia | Mih | Mic |

| kWh/m3 | % | kWh/t | kWh/t | kWh/t | ||

| MC-101 | 22.4 – 19.0 | 10.4 | 90.0 | 27.1 | 21.8 | 11.3 |

| MC-102 | 22.4 – 19.0 | 10.8 | 90.2 | 27.9 | 22.7 | 11.8 |

| MC-103 | 22.4 – 19.0 | 12.5 | 98.0 | 29.8 | 25.0 | 12.9 |

| MC-104 | 22.4 – 19.0 | 13.4 | 99.0 | 31.6 | 26.8 | 13.9 |

| Sample ID | A | B | sg | ta | SCSE | AxB |

| SMC | ||||||

| MC-101 | 89.7 | 0.30 | 2.76 | 0.25 | 12.2 | 26.9 |

| MC-102 | 100.0 | 0.26 | 2.76 | 0.24 | 12.4 | 26.0 |

| MC-103 | 83.5 | 0.28 | 2.91 | 0.21 | 13.7 | 23.4 |

| MC-104 | 80.5 | 0.27 | 2.89 | 0.19 | 14.2 | 21.7 |

Gravity Tests

• Gravity Recoverable Gold (GRG) test work was completed on MC-101, -102 and -103.

• All three MCs have a significant amount of coarse gravity gold.

• MC-101, MC-102 and MC-103 had a GRG of 93.0%, 94.9% and 75.8%, respectively.

• The gravity component is coarse to very coarse as seen in the Madsen and Satellite deposits.

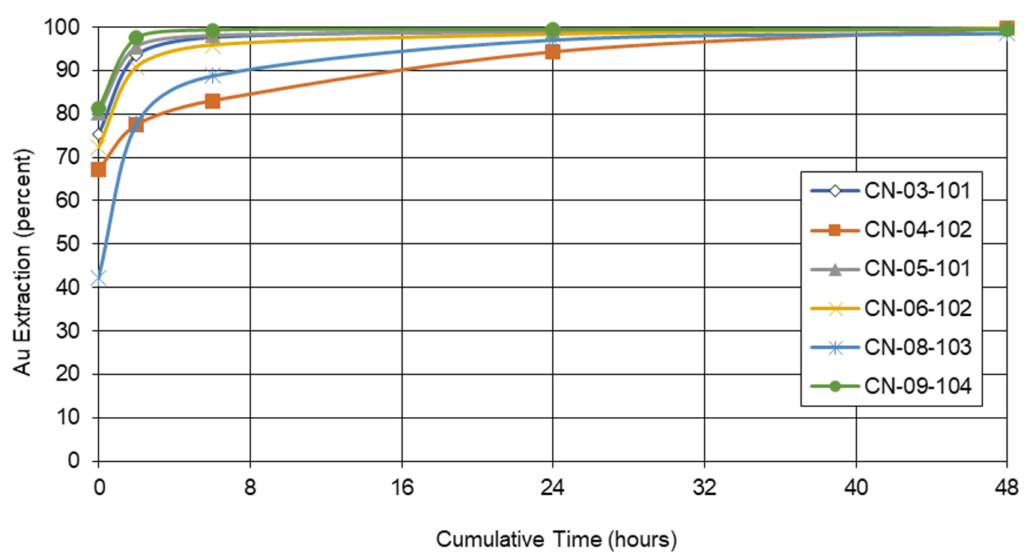

Leach Tests

• The leach tests were completed using the Madsen Mill Flowsheet.

• The gold extraction at 24 hours (residence time in the Madsen leach circuit) was above 95%for all four MCs tested with high gravity recovery – for comparison, the Madsen millaveraged 95%.

• The final extractions at 48 hours were above 98% with cyanide consumptions below 0.23 kg/tonne.

• High gravity recoveries to the pan concentrate of over 67% were recorded with the exception of MC-103 which had a recovery of 42.3%. Operational data from the Madsen mill averaged 45% recovery to the pan concentrate.

• Due to the coarse nature of the Rowan gold and slightly slower leach kinetics of MC-102 an additional leach tank will be added to the flowsheet.

• The Madsen detox circuit is designed for 1 hour residence time, 5:1 SO2:CNWAD and 30 mg/L CuSO4.5H2O with a target of less than 5 ppm CNWAD.

• The cyanide destruction test work completed on the MC’s indicates the Rowan material can achieve a final tailings CNWAD of less than 1 ppm Au following the Madsen design parameters and flowsheet.

Additional Test Work and Opportunities

Additional metallurgical test work at Rowan will include PFS-level studies to confirm extraction with varying head grades, as well as running the flowsheet on a number of variability samples from throughout the Rowan deposit.

DISCUSSION

The Rowan Mine Target consists of more than seven sub-parallel, near-vertical, east-west trending veins that are currently defined over a strike length of approximately 1.1 km– mineralization remains open along strike and at depth. The orientation of the veins at the Rowan Mine tend to follow the direction of D2 deformation, which is oriented in an east-west direction over this part of the property. Individual mineralized vein zones usually average 1.0 to 1.5m in thickness, with an overall thickness of the Rowan vein corridor at around 115m. Gold mineralization is typically localized within quartz-carbonate veins hosted within and along the ‘footwall’ margin of a porphyritic felsic intrusive, with increased grades often associated with the presence of visible gold and base metal sulphides (e.g. galena, sphalerite). High-grade dilation zones or ‘ore chutes’ along the Rowan vein trend have been recognized as important controls for localizing thicker and higher-grade zones of gold mineralization. The position and geometry of these dilation zones is well understood at Rowan.

The drilling completed at the Rowan Mine Target in 2023 has been focused on validating historical data across the Inferred Resource, and also infilling apparent gaps in the analytical data set which was a product of very selective sampling techniques implemented during previous drilling campaigns. Assay results received from the 2023 drilling program continue to confirm our thesis that quartz veining and gold mineralization continue at depth and along strike, with grades consistent with, or higher than those outlined in the current Inferred Mineral Resource which remains open in all directions. For example, the 100 Vein Zone – which is the furthest north vein currently modeled within the overall Rowan vein corridor – was previously interpreted to be a lower grade portion of the block model. Recent drilling has confirmed that higher grades are present within the 100 Vein Zone below 150m elevation, suggesting that gold grades are increasing at depth within this zone which is a trend that has been observed elsewhere in the Red Lake district. Drilling at the Rowan Mine Target area will continue with an emphasis on infill and expansion of the existing high-grade mineral resources.

QUALITY ASSURANCE/QUALITY CONTROL

Drilling completed at the Rowan Property consists of oriented NQ-sized diamond drill core. All drill holes are systematically logged, photographed, and sampled by a trained geologist at WRLG’s Mt. Jamie core processing facility. Minimum allowable sample length is 0.5m. Maximum allowable sample length is 1.5m. Standard reference materials and blanks are inserted at a targeted 5% insertion rate. The drill core is then cutlengthwise utilizing a diamond blade core saw along a line pre-selected by the geologist. To reduce sampling bias, the same side of drill core is sampled consistently utilizing the orientation line as reference. For those samples containing visible gold (“VG”), a trained geologist supervises the cutting/bagging of those samples, and ensures the core saw blade is ‘cleaned’ with a dressing stone following the VG sample interval. Bagged samples are then sealed with zip ties and transported by WRLGpersonnel directly to SGS Natural Resource’s Facility in Red Lake, Ontario for assay.

Samples are then prepped by SGS, which consists of drying at 105°C and crushing to 75% passing 2mm. A riffle splitter is then utilized to produce a 500g course reject for archive. The remainder of the sample is then pulverized to 85% passing 75 microns from which 50g is analyzed by fire assay and an atomic absorption spectroscopy (AAS) finish. Samples returning gold values > 10 g/t Au are reanalyzed by fire assay with a gravimetric finish on a 50g sample. Samples with visible gold are also analyzed via metallic screen analysis (SGS code: GO_FAS50M). For multi-element analysis, samples are sent to SGS’s facility in Burnaby, British Columbia and analyzed via four-acid digest with an atomic emission spectroscopy (ICP-AES) finish for 33-element analysis on 0.25g sample pulps (SGS code: GE_ICP40Q12). SGS Natural Resources analytical laboratories operates under a Quality Management System thatcomplies with ISO/IEC 17025.

West Red Lake Gold’s Rowan Property presently hosts a National Instrument 43-101 (“NI 43-101”) Inferred Mineral Resource of 2,790,700 t at an average grade of 9.2 g/t Au containing 827,462 ounces of gold with a cut-off grade of 3.8 g/tAu (NI 43-101 Technical Report, entitled “Technical Report and Resource Estimate on the West Red Lake Project” authored by John Kita, P.Eng., dated December 13, 2022 and filed December 30, 2022 on www.sedar.com). The Inferred Mineral Resource is located in the area of the historic underground Rowan Mine site and situated within a 1.8 km strike length portion of the regional scale Pipestone Bay St Paul Deformation Zone.

The technical information presented in this news release has been reviewed and approved by Will Robinson, P.Geo., Vice President of Exploration for West Red Lake Gold and the Qualified Person for exploration at the West Red Lake Project, as defined by NI 43-101 “Standards of Disclosure for Mineral Projects”.

ABOUT WEST RED LAKE GOLD MINES

West Red Lake Gold Mines Ltd. is a mineral exploration company that is publicly traded and focused on advancing and developing its flagship Madsen Gold Mine and the associated 47 km2 highly prospective land package in the Red Lake district of Ontario. The highly productive Red Lake Gold District of Northwest Ontario, Canada has yielded over 30 million ounces of gold from high-grade zones and hosts some of the world’s richest gold deposits. WRLG also holds the wholly owned Rowan Property in Red Lake, with an expansive property position covering 31 km2 including three past producing gold mines – Rowan, Mount Jamie, and Red Summit.

ON BEHALF OF WEST RED LAKE GOLD MINES LTD.

“Shane Williams”

Shane Williams

President & Chief Executive Officer

FOR FURTHER INFORMATION, PLEASE CONTACT:

Amandip Singh, VP Corporate Development

Tel: 416-203-9181

Email: investors@westredlakegold.com or visit the Company’s website at https://www.westredlakegold.com

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Certain statements contained in this news release constitute “forward-looking statements”. When used in this document, the words “anticipated”, “expect”, “estimated”, “forecast”, “planned”, and similar expressions are intended to identify forward-looking statements or information. These statements are based on current expectations of management, however, they are subject to known and unknown risks, uncertainties and other factors that may cause actual results to differ materially from the forward-looking statements in this news release and include without limitation, statements relating to the Rowan Property potential and the Company’s future objectives and plans.Readers are cautioned not to place undue reliance on these statements. West Red Lake Gold Mines Ltd. does not undertake any obligation to revise or update any forward- looking statements as a result of new information, future events or otherwise after the date hereof, except as required by securities laws.

Forward‐looking statements involve numerous risks and uncertainties and actual results might differ materially from results suggested in any forward-looking statements. These risks and uncertainties include, among other things, market volatility; the state of the financial markets for the Company’s securities; fluctuations in commodity prices and changes in the Company’s business plans. In making the forward looking statements in this news release, the Company has applied several material assumptions that the Company believes are reasonable, including without limitation, that the Company will continue with its stated business objectives and its ability to raise additional capital to proceed. Although management of the Company has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking statements or forward-looking information, there may be other factors that cause results not to be as anticipated, estimated or intended. There can be no assurance that such statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on forward-looking statements and forward-looking information. Readers are cautioned that reliance on such information may not be appropriate for other purposes. The Company does not undertake to update any forward-looking statement, forward-looking information or financial out-look that are incorporated by reference herein, except in accordance with applicable securities laws. The Company seeks safe harbor.

For more information on the Company, investors should review the Company’s continuous disclosure filings that are available at www.sedarplus.ca.